Why Lamination

A wide range of protection

Why You Should Laminate Your Printed Materials

Print lamination is a finishing process where a thin layer of plastic film is applied to printed materials. This layer provides an array of benefits, enhancing both the durability and appearance of the printed product. In this blog, we will explore the lamination process, discuss its advantages over unlaminated prints, and highlight common products and applications, including large format laminating.

The Print Lamination Process

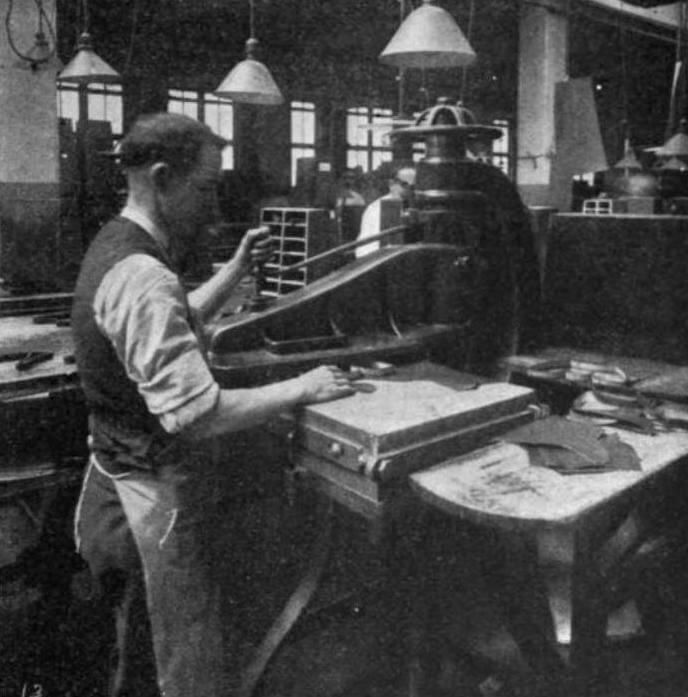

Lamination involves applying a protective plastic film to a printed piece using heat, pressure, or adhesive. The process can be done using various techniques, but the most common are thermal (heat-activated) lamination and pressure-sensitive (cold) lamination.

Thermal Lamination

In thermal lamination, the film has a heat-activated adhesive that bonds to the printed surface when passed through heated rollers. This technique is widely used due to its strong adhesion and versatility with different materials. Thermal laminates are generally lower in cost but require special equipment to apply the films to the printed substrate. Thermal films are generally applied at temperatures ranging from 240 to 310 degrees. Thermal lamination is the most common form when laminating both sides of your prints.

Pressure-Sensitive Lamination

Pressure-sensitive lamination uses films with a pre-applied adhesive that bonds to the printed surface when pressure is applied. This method is ideal for heat-sensitive materials or when a quick turnaround is needed. PSA (pressure sensitive adhesive) films have a higher cost than thermal laminates but can be applied with lower cost laminating equipment.

Benefits of Laminating Your Printed Materials

Laminating your printed materials offers several advantages over their unlaminated counterparts:

1. Protection

Lamination protects prints from physical damage, such as scratches, tears, and spills. The plastic film acts as a barrier against moisture, dirt, and UV rays, significantly extending the life of the print.

2. Enhanced Appearance

Laminated prints often have a more polished and professional look. The lamination can add a glossy or matte finish, enhancing colors and contrast, and making images and text pop. Specialty laminates such as a matte soft touch film often used for wedding invitations, booklet covers, and high-end packaging do wonders when trying to grab your clients’ attention.

3. Durability

Laminated materials are more resistant to wear and tear, making them ideal for frequently handled items. This increased durability is particularly beneficial for educational materials, menus, safety sheets and other high-use documents.

4. Ease of Cleaning

Laminated surfaces are easy to clean with a damp cloth, making them perfect for environments where hygiene is important, such as restaurants, hospitals, and schools. The use of a dry erase lamination also allows for repeated use.

Common Products That Use Lamination

Lamination is used across a wide range of products to improve their lifespan and appearance. Some common examples include:

1. Business Cards

Laminated business cards are more durable and resistant to damage, maintaining their professional look even after being handled frequently. The use of specialty films also help you stand out to your clientele.

2. Menus

Restaurant menus benefit from lamination as it protects them from spills and frequent handling, allowing them to be easily wiped clean.

3. Educational Materials

Flashcards, charts, and teaching aids are often laminated to withstand frequent use and to ensure longevity. Utilizing the dry erase film also allows for worksheets to be utilized multiple times instead of printing new worksheets for each use.

4. Brochures and Flyers

Laminated brochures and flyers have a higher quality feel and are less likely to be damaged during distribution.

5. ID Cards and Badges

Lamination helps protect the information on ID cards and badges, ensuring they remain legible and intact over time.

6. Posters and Large Format Signage

Lamination is very commonly used for posters, outdoor displays and marketing materials to provide weather resistant protection from rain, sun, and wind. By protecting your prints’ vibrant colors, lamination helps maintain color integrity therefore ensuring that your prints can endure long-term use without fading or degrading.

Summery

The print lamination process offers significant benefits by enhancing the durability, appearance, and functionality of printed materials. From business cards and menus to large format banners and posters, lamination is a valuable finishing technique that adds value to printed products. Whether for protecting frequently handled items or ensuring outdoor signage stands up to the elements, lamination is an essential step in producing high-quality, long-lasting printed materials.