The Evolution and Modern Marvels of Die-Cutting in Printing

The Evolution and Modern Marvels of Die-Cutting in Printing

The History of Die-Cutting

Die-cutting, a process that began in the early 19th century, revolutionized the printing and packaging industries. Initially, it was a labor-intensive manual process used for cutting leather for shoe manufacturing. With the advent of industrialization, die-cutting transitioned into the printing industry, allowing for precise and uniform cuts of various shapes and sizes. This innovation enabled the mass production of intricate designs on paper and other materials, significantly reducing production time and costs.

Technological Advancements in Die-Cutting

Recent advancements in die-cutting technology have greatly enhanced precision, speed, and versatility. Here are some of the modern machines and technologies revolutionizing the industry, along with their strengths and weaknesses:

Traditional Die-Cutters Traditional die-cutters, often referred to as "flatbed die-cutters," use steel rule dies to cut materials. These machines are highly reliable for large-scale production runs, offering consistency and durability.

- Strengths:

High precision and consistency; durable; suitable for large production runs; can cut a wide range of materials, including rubber. - Weaknesses:

Requires the creation of physical dies, which can be time-consuming and costly; less flexibility for small runs and custom jobs. - Learn more: Wikipedia

Rotary die cutters use cylindrical dies, which roll over the material, cutting intricate shapes with unparalleled accuracy. This technology is particularly advantageous for high-volume production runs and complex designs.

- Strengths:

High-speed production; excellent for intricate and complex designs; ideal for high-volume runs. - Weaknesses:

May not be suitable for cutting thicker materials like rubber; initial setup costs can be high. - Discover more: Flexography and Markwide Research

Laser Cutters Laser die-cutting is a non-contact process that uses a laser to cut materials. This technology offers incredible precision and the ability to cut detailed and intricate designs without the need for physical dies.

- Strengths:

Extremely precise and detailed cuts; no need for physical dies, allowing for quick adjustments and prototyping; can cut a wide range of materials, including paper, plastics, and metals. - Weaknesses:

Slower than traditional and rotary die-cutting for large runs; not suitable for materials that can be damaged by heat, such as certain synthetics and rubber. - Explore laser die-cutting: PrintWeek

Digital Die Cutters are known for their versatility and ease of use. These machines use digital technology to create custom cuts without the need for traditional dies.

- Strengths:

Highly customizable and ideal for short-run jobs; quick setup with no need for physical dies; great for on-demand printing services and small production runs. - Weaknesses:

Limited in cutting thicker and tougher materials like rubber; generally slower than traditional and rotary die cutters for high-volume jobs. - Read about digital die-cutting advancements: PrintWeek

Materials and Applications

Modern die-cutting technologies can handle an impressive array of materials, making them indispensable in various industries. Here are some of the materials and applications:

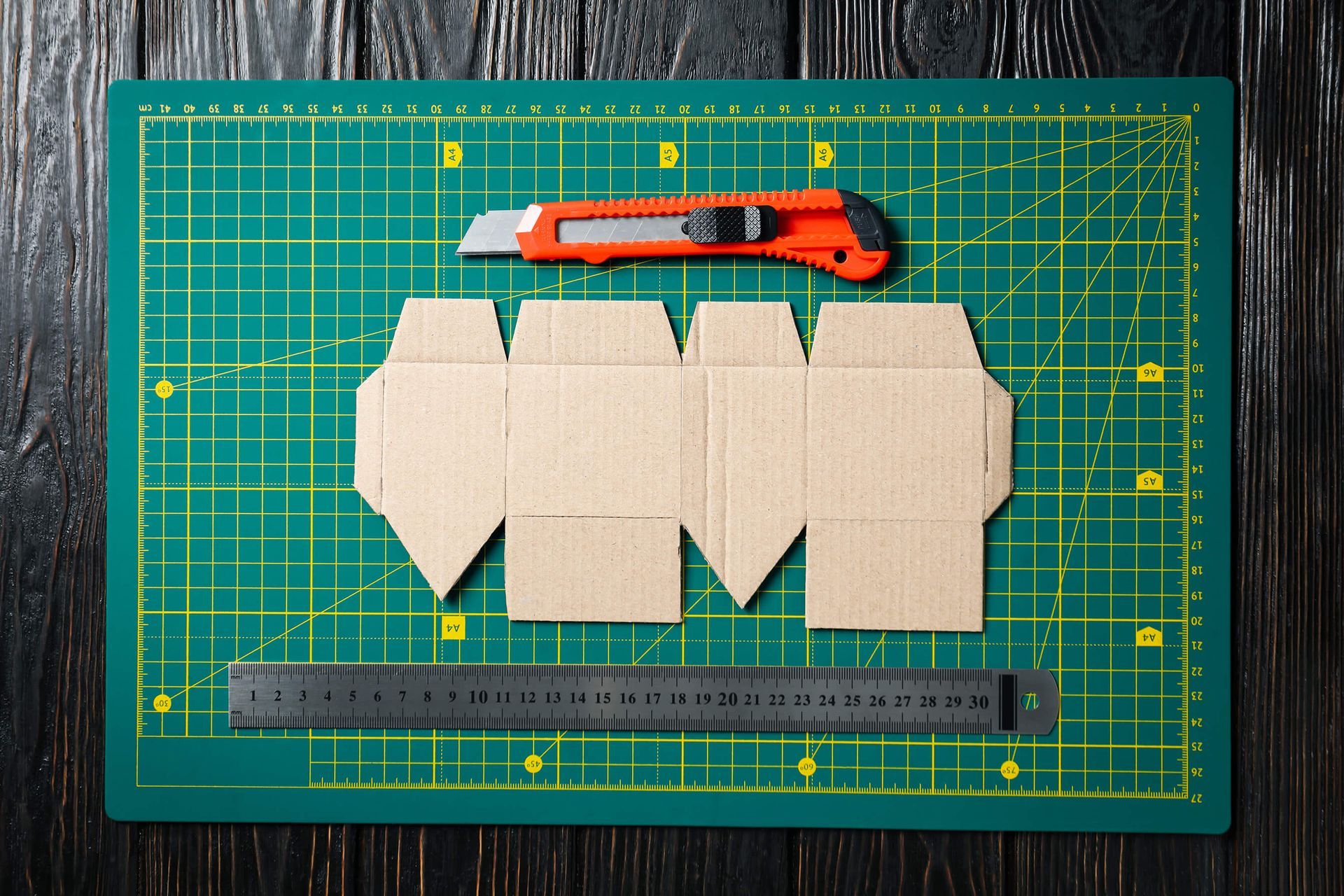

Paper and Cardstock The most common materials for die-cutting, used extensively in packaging, greeting cards, and marketing materials.

Synthetics and PVC With advancements in printing technologies, many printers can now print on synthetic materials and PVC, expanding the range of products that can be die-cut. These materials are used in creating durable items like signage, labels, and ID cards.

Rubber Die-cutting is crucial in the production of items like counter mats and mouse pads. After printing and mounting the rubber, these products are die-cut into the desired shapes, ensuring precision and consistency. Note that not all die-cutting technologies can handle rubber effectively.

Specialty Applications Die-cutting is also used in creating custom packaging, promotional items, and intricate marketing materials. Examples include custom-shaped business cards, stickers, and intricate packaging designs that enhance product appeal.

Examples of Modern Die-Cutting Machines

- Traditional Die-Cutter

- High precision, durable, ideal for large production runs.

- Rotary Die Cutter

- High-speed, accurate, suitable for complex designs and high-volume runs.

- Laser Cutter

- Precise, versatile, perfect for detailed and intricate cuts on various materials.

- Digital Die Cutter

- Digital interface, customizable, ideal for short-run jobs and quick adjustments.

Conclusion

Die-cutting has come a long way since its inception, evolving into a critical process in the printing and packaging industries. The integration of modern technologies has not only increased the efficiency and precision of die-cutting but also expanded the range of materials and applications. From traditional die-cutters to advanced laser and digital cutters, the options are vast and continually improving. Whether you are producing high-volume packaging or custom promotional items, modern die-cutting technologies offer the tools needed to bring your creative visions to life.

By exploring these advancements, you can stay ahead in the industry and offer innovative solutions to your clients.

For more information on the latest advancements in die-cutting technology, visit these resources: