Sustainability in the Print Industry: A Financial and Environmental Perspective

Sustainability in the Print Industry: A Financial and Environmental Perspective

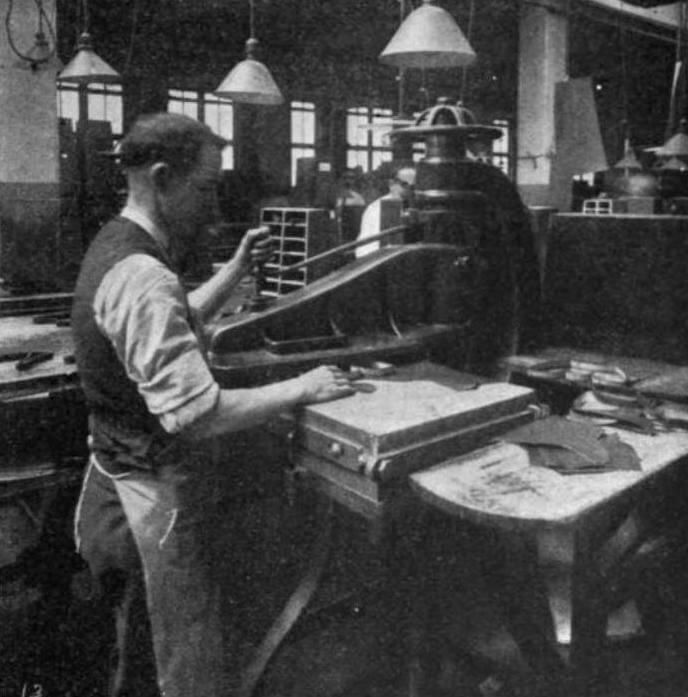

The print industry has been making significant strides in sustainability over the past decade, driven by innovations that reduce power consumption, minimize waste, and optimize material usage. These advancements not only benefit the environment but also have a positive financial impact, allowing print companies to offer competitive pricing to their customers. Here's a closer look at how these improvements are being implemented and how they affect the cost to the end consumer.

Power Consumption

Energy-Efficient Equipment: Modern printing presses and digital printers in the U.S. and globally are designed to consume less power. Innovations such as variable speed motors, more efficient drying systems, and LED curing technology are leading the charge in reducing energy usage.

Renewable Energy Sources: In the U.S., some print shops are actively transitioning to renewable energy sources. While a few larger facilities have installed their own solar panels or wind turbines, the majority are opting to purchase renewable energy from their utility providers. This choice lowers overall energy costs over time and aligns with broader sustainability goals.

Global Perspective: Outside the U.S., particularly in regions with higher renewable energy adoption rates, print shops are more likely to invest in personal renewable energy systems. This is due to different governmental incentives and infrastructure availability.

Financial Impact: Reduced power consumption lowers operational costs, which can translate into more competitive pricing for consumers. The adoption of renewable energy, whether through direct installation or purchasing green energy, helps stabilize energy costs in the long run.

Waste Reduction

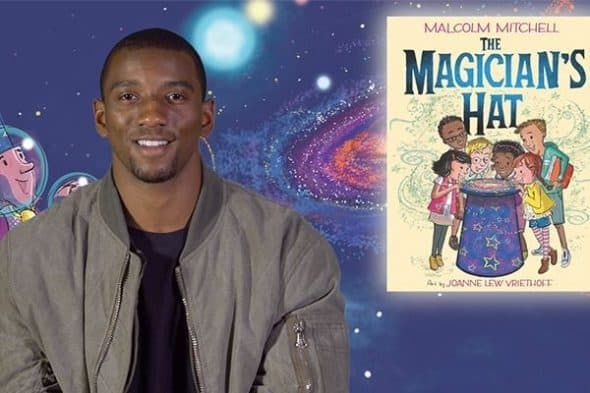

Digital Printing: The shift from traditional to digital printing has significantly reduced waste across the industry. In the U.S., digital printing requires less setup and produces less waste during production because there are no plates or chemicals involved.

On-Demand Printing: On-demand printing, popular in both the U.S. and globally, minimizes overproduction and reduces the amount of unsold printed material that would otherwise be discarded.

Efficient Layouts and Automation: Advanced software tools optimize print layouts to maximize paper usage, reducing paper waste. Automation in cutting and finishing also reduces errors and material waste.

Financial Impact: Reduced waste translates to lower material costs, allowing these savings to be passed on to consumers. Additionally, reducing waste minimizes the need for disposal services, further lowering operational costs.

Ink and Toner Usage

High-Efficiency Inks and Toners: New formulations of inks and toners are offering higher coverage with less material, with significant adoption seen in both U.S. and international markets. Improved precision in application reduces overuse, and ink recycling systems are becoming more common in the U.S., minimizing the need for new ink purchases.

Inkjet Technologies: Inkjet printers, especially in industrial applications, use precise droplet control to reduce ink consumption while maintaining high print quality.

Financial Impact: Lower ink and toner usage reduces the cost per print, which can be reflected in lower prices for consumers. Efficient ink usage also reduces the frequency of purchasing new supplies, contributing to cost savings.

Better Use of Materials

Recycled and Sustainable Paper: The use of recycled and sustainably sourced paper has increased globally, with U.S. print shops leading the way. Certifications like FSC (Forest Stewardship Council) support these efforts, not only enhancing environmental stewardship but also potentially lowering costs through bulk purchasing agreements.

Bio-based and Eco-Friendly Inks: The development of bio-based inks, which are less harmful to the environment, is advancing both in the U.S. and abroad. These inks help printers meet sustainability goals without significantly increasing costs.

Financial Impact: Sustainable material choices often come with cost incentives, such as subsidies or tax breaks, which can be passed on to consumers in the form of lower prices. Additionally, using recycled materials can sometimes be more cost-effective than virgin materials, contributing to overall cost efficiency.

Improved Efficiency and Automation

Automation and AI: Modern printing processes are increasingly automated, with AI-driven systems optimizing production, reducing errors, and speeding up turnaround times. This efficiency is evident in both U.S. and international markets, as printers seek to lower resource usage per job, thus reducing costs.

Lean Manufacturing Practices: Many U.S. print shops, along with their international counterparts, are adopting lean manufacturing practices to eliminate waste and improve efficiency, further reducing costs.

Financial Impact: Increased efficiency lowers labor and material costs, which can be passed on to consumers in the form of lower prices. Faster production times also mean more jobs can be completed in the same timeframe, increasing overall profitability.

Conclusion

The print industry's continuous improvements in sustainability have a direct and positive financial impact. By reducing energy consumption, waste, and material use, printers can lower their operational costs. These savings can then be passed on to the end consumer in the form of more competitive pricing. Additionally, adopting sustainable practices can enhance a company's reputation, potentially attracting more customers who value environmentally responsible businesses.

- References for Further Reading:

- Energy Efficiency in Printing: You can explore the latest energy efficiency initiatives for commercial printing through the Homepage | ENERGY STAR

- Renewable Energy Adoption in Printing: For information on how the printing industry is adopting renewable energy, refer to the EPA's Green Power Partnership.

- Waste Reduction and Digital Printing: The Sustainable Green Printing Partnership (SGP) offers insights into sustainable practices in the print industry, including waste reduction.

- Inks and Toners Efficiency: The Print Action website frequently publishes articles on advancements in sustainable inks and toners.

- Recycled Materials in Printing: Learn more about FSC-certified papers and sustainability in printing on the [Forest Stewardship Council (FSC)] website: https://fsc.org/en