The Power of Counter Mats in Marketing

The Role of Counter Mats in Marketing

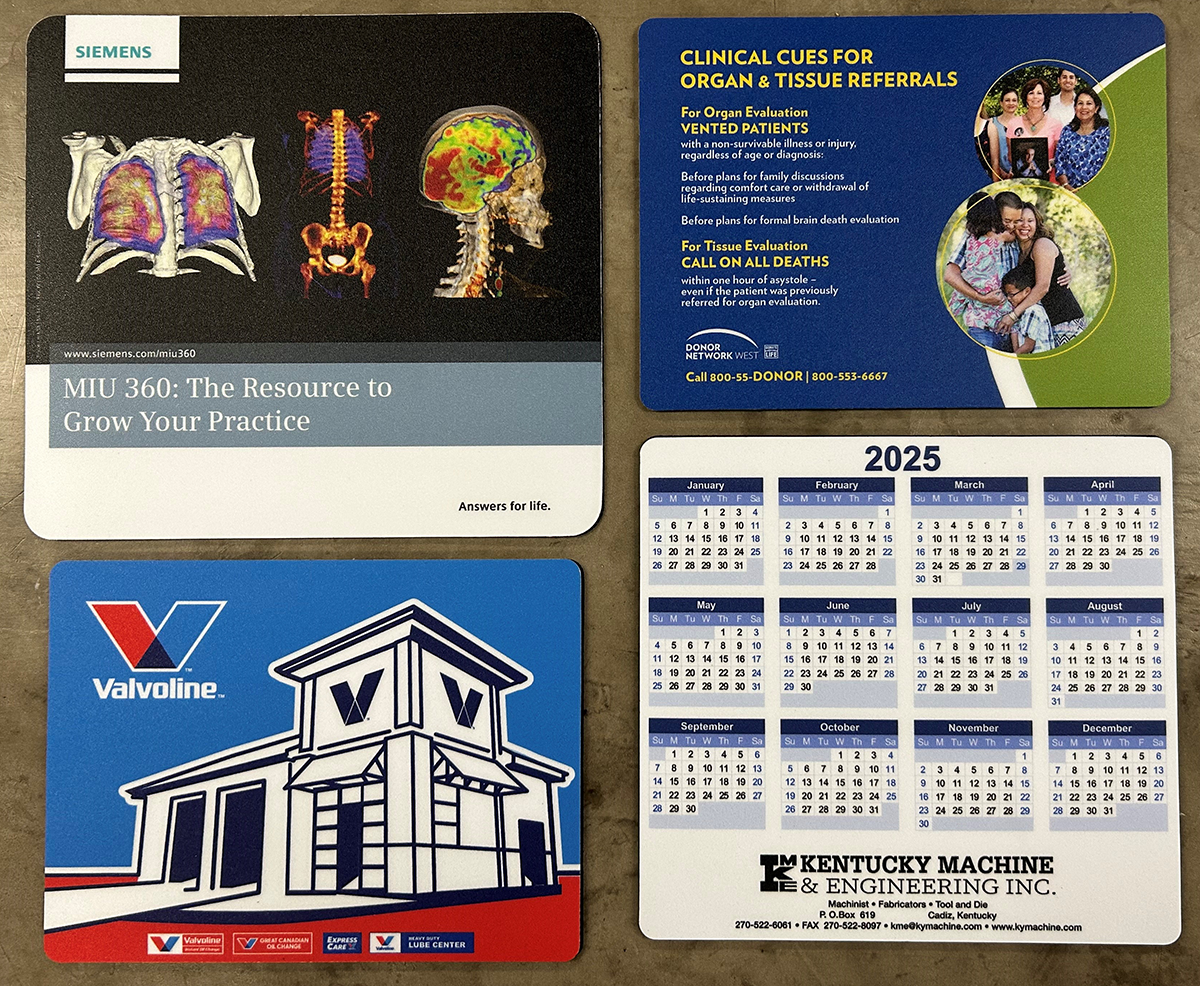

Counter mats are an often overlooked but highly effective tool in point of sale (POS) marketing. Typically found on counters in retail stores, restaurants, and service centers, these mats serve as a durable and eye-catching medium to convey marketing messages directly to customers at the point of purchase.

Common Uses of Counter Mats

Counter mats are versatile and can be seen in various settings:

Retail Stores:

They promote special offers, new product launches, or seasonal sales.

Restaurants and Cafes: Menus, specials, and promotions are displayed prominently.

Service Centers:

They inform customers about services, memberships, or loyalty programs.

Counter mats ensure high visibility and engagement with customers by strategically placing where transactions occur.

Branding Messages Conveyed Through Counter Mats

Counter mats are an extension of a brand’s marketing strategy. They can communicate:

- Promotions and Discounts: Highlighting limited-time offers or discounts.

- New Products: Introducing new items or services.

- Brand Values and Messaging: Reinforcing brand identity and values through consistent visual and textual messaging.

These mats keep customers informed and engaged while reinforcing brand awareness and loyalty.

Benefits of Point-of-Sale Marketing

Point-of-sale marketing leverages the critical moment when customers are ready to make a purchase. The benefits include:

- Increased Impulse Purchases: Eye-catching visuals and compelling messages can prompt spontaneous buying decisions.

- Enhanced Customer Experience: Providing valuable information or offers can enhance customer satisfaction and loyalty.

- Maximized Marketing Impact: By targeting customers at the point of purchase, brands can ensure their messages are seen and acted upon immediately.

Quality Differences: Paper Stock vs. Synthetic or Vinyl Substrates

The choice of substrate for counter mats significantly impacts their durability, appearance, and overall effectiveness.

Paper Stock:

Some manufacturers choose to use a standard offset paper stock as the printed substrate for their counter mat production. While the printed paper stock is protected on the surface by scratch-resistant vinyl laminate, paper stocks are still susceptible to moisture and can damage easily in high-traffic areas. Counter mats produced with a paper stock are not suggested in areas that require the surface to be cleaned on multiple occasions throughout the day. This often leads to “delamination”, which is when the paper fibers are easily separable between the protected top layer and the base layer. This leads to the counter mats being discarded thereby no longer communicating the message intended.

Pros:

- Cost-Effective: Cheaper to produce, making it ideal for short-term promotions.

- Eco-Friendly Options: Recyclable paper stocks are available.

Cons:

- Less Durable: Prone to wear and tear, especially in high-traffic areas.

- Limited Lifespan: Susceptible to moisture and physical damage.

Synthetic or Vinyl Substrates:

High-quality counter mat manufacturers use synthetic papers or PVC as their printed substrate for their counter mat production. The printed synthetic substrate is still protected by a scratch-resistant vinyl laminate which protects the printed area. This combination constructs a counter mat that can withstand moisture and can handle high-traffic areas. Depending on the thickness of the printed substrate, it can also withstand potentially damaging objects being placed on it such as car parts, paint cans, and other heavy items. If your potential advertising area requires your counter mat to withstand the abuse of these types of items, a 20-mil styrene would be the suggested printed substrate.

Pros:

- Durability: Resistant to water, spills, and heavy use, ensuring a longer lifespan.

- High-Quality Print: Offers vibrant colors and sharper images for a more professional look.

- Easy to Clean: Can be wiped clean, maintaining a neat appearance.

Cons:

- Higher Cost: More expensive to produce compared to paper stock.

- Environmental Impact: Not as easily recyclable, though some options are more eco-friendly than others.

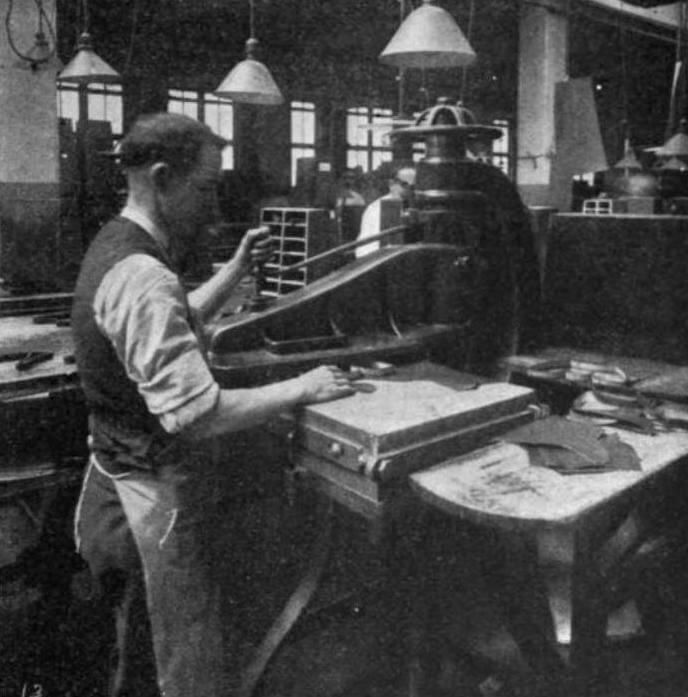

Quality Differences: Counter Mat Backing Materials

Counter mats are available with a multitude of backings. The most common backings found on counter mats are natural rubber, foam, PVC, repositionable adhesive, and non-skid film. Natural rubber backings are used in heavier-duty applications and provide a level of protection to the surface from heavy items being set on the counters. This is ideal for auto part stores or hardware stores. For a low-profile mat, a repositionable adhesive is an excellent option. This construction is used by state lotteries and placed in convenience stores. This is ideal for locations that have high traffic but do not need to provide any protection to the counter surface. As a substitute for the higher cost of natural rubber, there are different types of foam backings and “synthetic” rubber or PVC.

Natural Rubber:

Natural rubber is durable, and the most common backing used for counter mats. Often referred to as “Heavy Duty”, a rubber-backed counter mat not only has a marketing purpose but also protects the counter surface. The weight of the rubber keeps the counter mat in place while also allowing it to be moved to different locations. The rubber backing is available in multiple thicknesses. The most common are 1/16” or 1/8”, but some heavier-duty applications may require a ¼” thickness.

Pros:

- Durability: Rubber is the most durable backing.

- Eco-Friendly: Natural rubber is an eco-friendly backing.

Cons:

- Higher Cost: Rubber is the premium backing and carries a higher cost.

- Weight: Rubber is heavy increasing the shipping cost of the counter mats throughout the delivery process.

PVC:

As an alternative to natural rubber, a PVC backing looks like rubber and can also protect the counter surface. It is durable and can handle most of the requirements of a natural rubber counter mat. This makes it a popular choice for those who want the natural rubber backing benefit but need to save on cost. Most often it is available in the 1/8” thickness.

Pros:

- Durability: PVC is a very durable product used in a lot of applications requiring durability.

- Lower Cost: PVC offers a lower price point than natural rubber.

- Weight: PVC is lighter than natural rubber, lowering the shipping costs of the counter mats throughout the delivery process.

Cons:

- Environmental Impact: Not as easily recyclable.

Repositionable adhesive:

Repositionable adhesive-backed counter mats are mostly used in convenience stores or other high-traffic areas that require a low-profile surface that blends in well with the counter. This highly cost-effective backing makes it an excellent option for a counter mat.

Pros:

- Durability: If the repositionable adhesive is used with a synthetic paper or PVC printed substrate, it is a very durable product and can be cleaned repeatedly.

- Lower Cost: Repositionable adhesive offers a low price point in comparison to other backings.

- Weight: The lightest of the backing options, the repositionable adhesive provides the lowest shipping costs for the counter mats throughout the delivery process.

Cons:

- Environmental Impact: Not as easily recyclable.

Foam:

There are a few foam backing options for counter mats. The most durable of the foam options would be the EVA foam. EVA is a highly used material in shoes, so it is a durable product. It is lightweight but does slide around on the counter as it does not have very good non-skid properties. Some manufacturers will use polyurethane (PU) foam. This is the least durable backing and is not suggested to be used in this application. Please avoid PU foam at all costs. This is a packaging foam, not a durable backing material. SBR is a “manmade” rubber and feels like foam. This provides better non-skid properties than the EVA and PU foams. It is comparable to the EVA in durability and is more durable than the PU foam. Most foams are offered in the 1/8” thickness.

Pros

- Lower Cost: The foam backing options offer a low price point in comparison to other backings.

- Weight: Foam provides a lighter weight helping lower shipping costs of the counter mats throughout the delivery process.

Cons:

- Durability: Although the EVA foam is somewhat durable, the foam backings in general are the least durable of the backing options.

- Environmental Impact: Not as easily recyclable.

Summary

Counter mats are a powerful tool in the arsenal of point-of-sale marketing. By choosing the right substrate and designing compelling visuals, brands can effectively capture customer attention, drive sales, and reinforce their marketing messages right where it matters most. Whether opting for cost-effective paper stock for short-term promotions or durable synthetic or vinyl for long-term use, the strategic use of counter mats can yield significant benefits for any marketing campaign.